In today’s rapidly evolving technological landscape, smart manufacturing 4.0 has emerged as a groundbreaking concept that is revolutionizing the industrial sector. With its integration of cutting-edge technologies such as artificial intelligence, big data analytics, and Internet of Things (IoT), smart manufacturing 4.0 promises to enhance productivity, efficiency, and sustainability in factories worldwide.

The Power of Smart Manufacturing 4.0

Smart manufacturing 4.0 encompasses a range of innovative solutions that leverage advanced technologies to optimize production processes and enable real-time decision-making capabilities. By connecting machines, systems, and people through IoT networks, manufacturers can achieve seamless communication and collaboration across all levels of their operations.

This transformative approach enables predictive maintenance by continuously monitoring equipment performance using sensors and data analysis algorithms. It allows for proactive identification of potential issues before they escalate into costly breakdowns or disruptions in production lines.

Furthermore, with the aid of artificial intelligence algorithms integrated into smart manufacturing systems, factories can analyze vast amounts of data collected from various sources to identify patterns and trends that would otherwise go unnoticed by human operators alone. This invaluable insight empowers manufacturers to make informed decisions regarding process optimization strategies or product quality improvements.

JVTECH: Pioneering Smart Manufacturing Innovations

One notable player at the forefront of driving smart manufacturing advancements is JVTECH – a leading technology company specializing in industrial automation solutions.

Through their expertise in developing intelligent robotics systems equipped with machine vision capabilities, JVTECH has successfully enabled automated inspection processes within factory environments. These robotic systems utilize sophisticated cameras combined with AI algorithms to detect defects or anomalies during production cycles swiftly.

By implementing JVTECH’s state-of-the-art solutions, manufacturers can significantly reduce human error and enhance product quality assurance. This not only saves time and resources but also ensures consistent output that meets the highest industry standards.

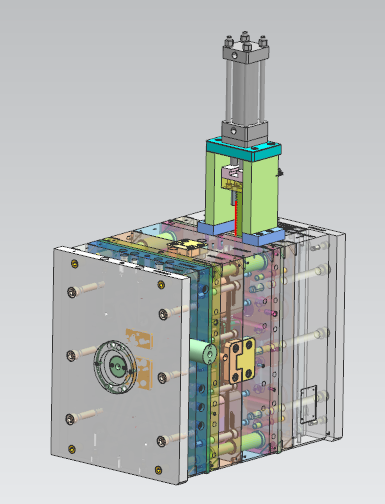

The Promise of 2k Molding in Smart Manufacturing

Another key aspect of smart manufacturing 4.0 is the adoption of advanced molding techniques such as 2k molding. This innovative process involves combining two different materials or colors into a single molded part, resulting in enhanced functionality and aesthetics.

By integrating 2k molding into their production lines, manufacturers can achieve greater design flexibility while reducing assembly steps and overall costs. The ability to create complex parts with varying material properties within a single mold enhances efficiency and streamlines the manufacturing process.

In addition to its cost-saving benefits, 2k molding also contributes to sustainability efforts by minimizing waste generation through optimized material usage. With precise control over material distribution during the injection molding process, manufacturers can minimize scrap rates and maximize resource utilization.

The Future of Smart Manufacturing 4.0

As smart manufacturing continues to evolve rapidly, it holds immense potential for revolutionizing industries across the globe. By harnessing technologies like AI, IoT, and advanced robotics systems offered by companies like JVTECH, factories can unlock new levels of productivity, efficiency, and quality assurance.

With ongoing advancements in smart manufacturing processes such as 2k molding further enhancing design possibilities while optimizing resource consumption, we are witnessing an era where traditional manufacturing practices are being transformed into highly intelligent systems capable of meeting ever-increasing demands efficiently.