What is Prototype CNC Machining?

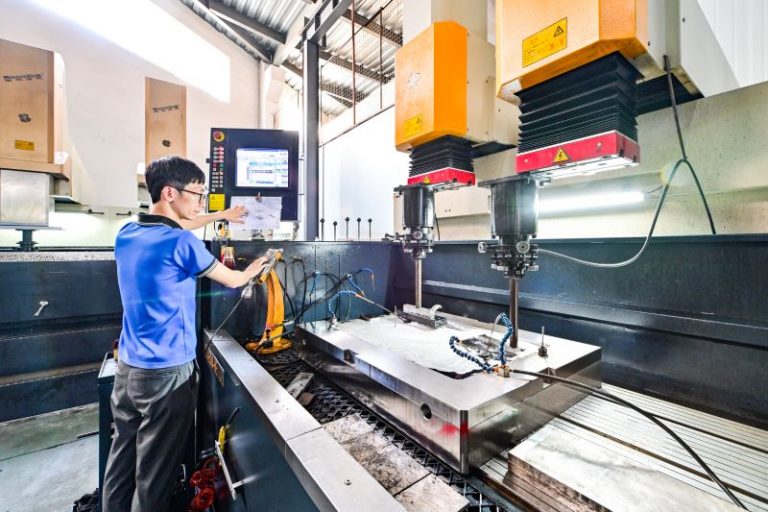

Alright, let’s dive into the exciting world of prototype CNC machining. If you’re in manufacturing or design, you’ve likely heard about it, but do you really know what it involves? Essentially, prototype CNC machining is a process where computer-controlled tools create precise parts through subtractive manufacturing. This is where you take a solid block of material and carve away what you don’t need, leaving you with a tailored piece that fits your specifications perfectly. The beauty of this method lies in its ability to produce highly complex shapes and features that traditional machining just can’t touch. Examples range from intricate brackets to custom housings for electronic devices. With the rise of digital fabrication, it’s never been easier to bring your concepts to life! Your idea can go from a simple sketch to a tangible piece of machinery in no time, keeping innovation flowing in fast-paced industries.

Enhancing Your Prototyping Process

Now let’s talk about how prototype CNC machining can dramatically enhance your prototyping process. Imagine you’re working on a new product, and you need to validate your design before full-scale production. This is where CNC prototyping truly shines! The quick turnaround time means you can create, test, and refine your prototypes in a fraction of the time. For instance, consider a startup developing a new gadget. With traditional prototyping methods, they might be waiting weeks for components to arrive. With CNC machining, they can have a functional prototype ready within days or even hours! This not only saves time but also costs, as production adjustments can be made on-the-fly, allowing for rapid iteration. Plus, the accuracy of CNC machining ensures your prototypes mirror the final product closely, minimizing surprises during mass production. In the end, you’re not just creating a prototype; you’re creating a reliable blueprint for success!

Maximizing the Benefits of CNC Prototyping

To truly maximize the advantages of CNC prototyping, it’s important to consider material selection carefully. Each material behaves differently during machining, and understanding these characteristics can drastically impact your project’s outcome. For example, aluminum is often favored for its strength and lightweight properties, making it perfect for aerospace applications. On the other hand, more complex designs might require plastics or composites for better flexibility and surface finish. Knowing when to use which material can save you both time and money. Moreover, collaborating with experienced machinists can lead to better recommendations on design alterations that will optimize your prototype’s performance. They can provide insights from past projects that could help you avoid common pitfalls. This thoughtful approach ensures that when your idea hits the production line, it’s ready for anything that comes its way!

Conclusion: Why Choose APT-Mold?

In conclusion, prototype CNC machining is not just a tool; it’s a game-changer for anyone in the industry looking to innovate and streamline their production process. From the rapid design iterations to the cost-effective solutions it provides, the benefits are abundant. When you’re looking for a reliable partner in this journey, look no further than APT-Mold. Known for their expertise in manufacturing, they bring unmatched supply advantages, ensuring your prototypes are not only built to perfection but delivered on time. With APT-Mold at your side, you’re choosing more than just a service provider; you’re choosing a partner dedicated to fueling your success in prototype CNC machining!