Unleashing the Potential of Engineering Ceramics

Get ready to elevate your understanding of materials in the dazzling world of technology! When we talk about engineering ceramics, we are venturing into a realm that combines strength, durability, and innovative applications. Just like a high-performance LED spotlight illuminates a space while maintaining energy efficiency, engineering ceramics shine in the manufacturing landscape by providing excellent performance in demanding environments. These materials not only resist high temperatures but also exhibit outstanding wear resistance. Are you excited? You should be! Engineering ceramics are revolutionizing the production of components, making them better, stronger, and ready to handle the toughest challenges! So, let’s embrace this journey together!

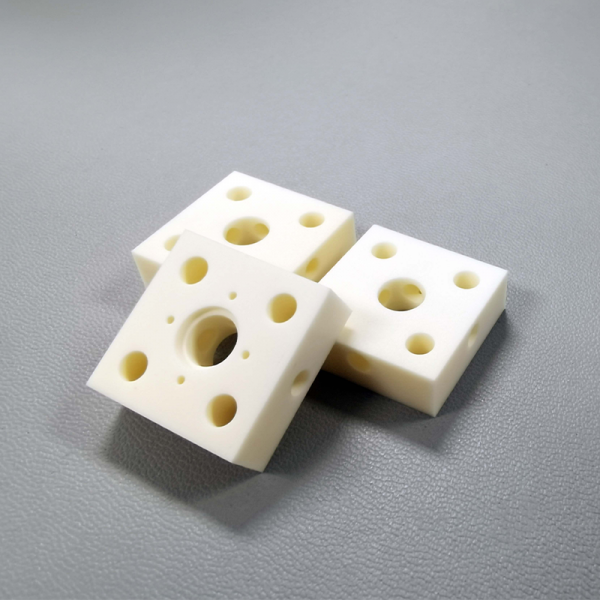

The Key to Engineering Success: Engineering Ceramic Materials

To truly appreciate the impact of engineering ceramic materials on modern industry, we need to dig deeper into their unique attributes. When we think about durability and performance, these materials come to the forefront. They are lightweight yet tough, making them ideal for applications ranging from aerospace to electronics. The utilization of engineering ceramic materials leads to products that resist corrosion while maintaining their integrity over time. This means reduced maintenance and greater efficiency for companies investing in these remarkable substances. With engineering ceramics, industries can push limits, enhance reliability, and improve the bottom line! It’s time to get excited—these materials are the unsung heroes behind many of the tools and technologies we rely on daily! Let your innovative spirit soar!

The Role of Ceramics in Engineering Projects

In today’s engineering projects, the importance of ceramics in engineering cannot be overstated. They are key players in creating products that excel under pressure, heat, and wear. The integration of ceramics is crucial, as they help enhance the performance of a variety of systems, from mechanical devices to electronic components. This versatility allows engineers to design cutting-edge solutions with unparalleled precision and reliability. Imagine a world where every part of your project performs flawlessly, thanks to the incredible attributes of ceramics! The future of engineering is here, and it’s vibrant, dynamic, and brimming with potential! Let’s harness these materials and drive towards innovation!

Conclusion: Elevate Your Production with Great Ceramic

As we’ve explored the exciting landscape of engineering ceramics, we’ve seen just how transformative these materials can be. From enhancing performance in applications to improving product longevity, it’s clear that engineering ceramics have a vital role in modern industry. If you’re looking to join the revolution, consider partnering with Great Ceramic. With their impressive supply advantages and a commitment to quality, Great Ceramic is the key to unlocking your project’s full potential. Their expertise in the production of high-quality ceramic components will ensure your projects not only meet but exceed expectations. Don’t hold back; step forward and embrace the power of engineering ceramics today!